This book outlines the journey of the greatest company, contract manufacturing, and its impact. The author of this book has an outstanding background in this domain. Let’s explore some key points of this book, and we are pretty sure you will come to know something new.

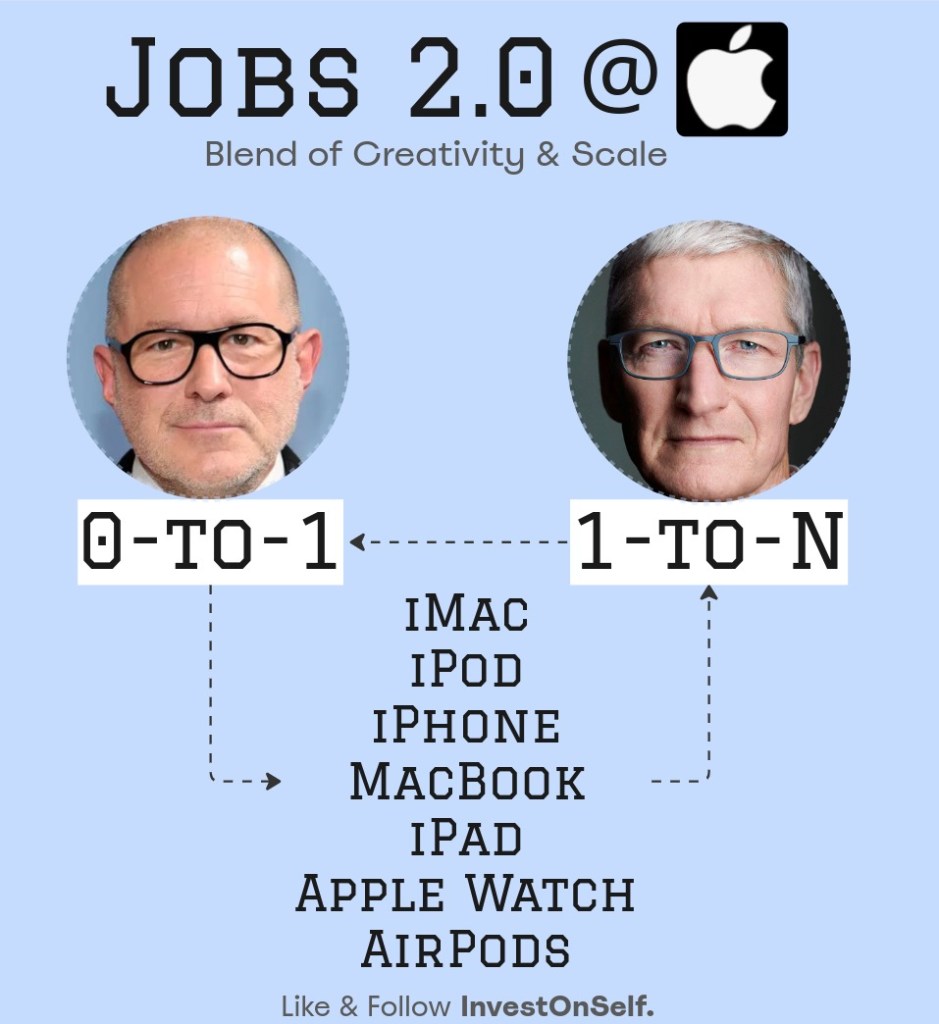

Steve Jobs 2.0:

In 1997, on his return back to Apple, Steve held several meetings to make a turnaround plan for the existential crisis. The portfolio of products was large but lacked a wow factor, and he exclaimed that “the products suck”.

He visited the ID team led by Jony Ive and found the previous CEO & development team never considered the ID team’s proposed design. From that moment onwards, the ID Team was at the top of the pyramid structure organisation to take creative design decisions for products.

Also, manufacturing at a huge scale with proper quality is quite a challenge. It was expensive and difficult to manage unions and suppliers to manufacture products in the US. Tim Cook joined the messy Apple operations team from a well-run business company known as Compaq. So, his past experience dealing with suppliers, granular level of understanding of the supply chain and photographic memory helped the Apple operation to scale towards the north with the efficient cost.

So a blend of creativity and supply chain is essential for the growth of any product-based company.

“Apple knows the manufacturing well, without being a manufacturer, like Uber.”

Project Purple:

On January 9, 2007, six months before the launch of the iPhone, Steve Jobs demoed in a packed auditorium. The features, including full-screen web navigation with basic multi-touch features, were eye-openers for the audience.

A few weeks after the unveiling of the iPhone, he walked into the meeting and threw the prototype phone onto the boardroom table as it got scratches from the keys in his pocket because of its plastic screen. And he demanded, “Make it glass.”

But the prototype iPhone with a glass screen failed the one-metre drop test one hundred times out of one hundred times. Then Steve Jobs reached out to the CEO of Corning Glass, who pioneered ceramic shield precision glass, aka Gorilla Glass.

Since 2007, Corning Glass has partnered with Apple for products like the iPhone and Apple Watches.

“Work hard on the job today or work hard to find a job tomorrow.” – Terry Gou

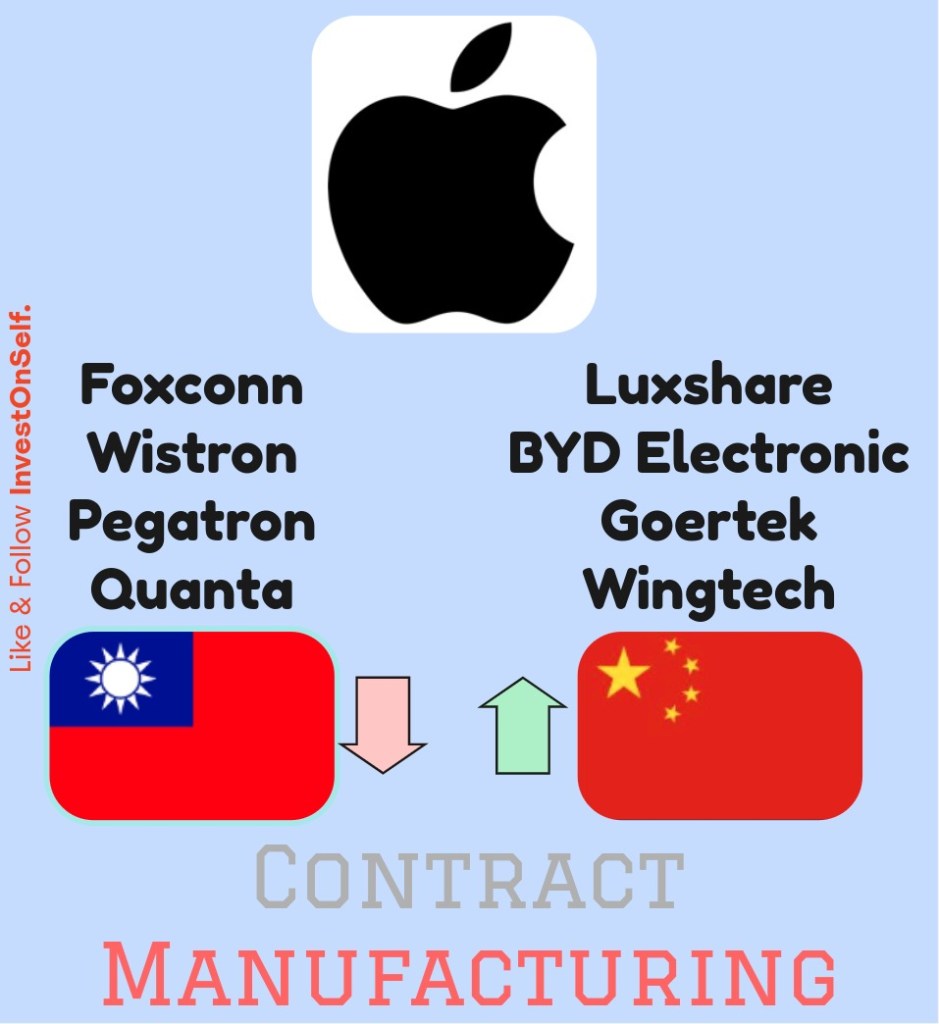

Contract Manufacturing:

Apple wanted to manufacture their products in the US Fremont manufacturing unit, aka the factory of the future. But it was not going according to plan with respect to cost, delivery timeline, volume, etc.

Meanwhile, the other part of the world, Asia, looked lucrative for manufacturing with low labour costs, no union and fewer complaints from employees about long, monotonous work. Initially contract manufacturing started with Taiwan-based companies in China, and then Chinese companies started to gain share. The companies like Foxconn, Pegatron, LuxShare, etc., flourished by making different parts of the Apple products.

Apple focused on product development, dissolved the Fremont factory by 1992 and used contract manufacturing for Apple products.

“Apple knows the manufacturing well, without being a manufacturer, like Uber.”

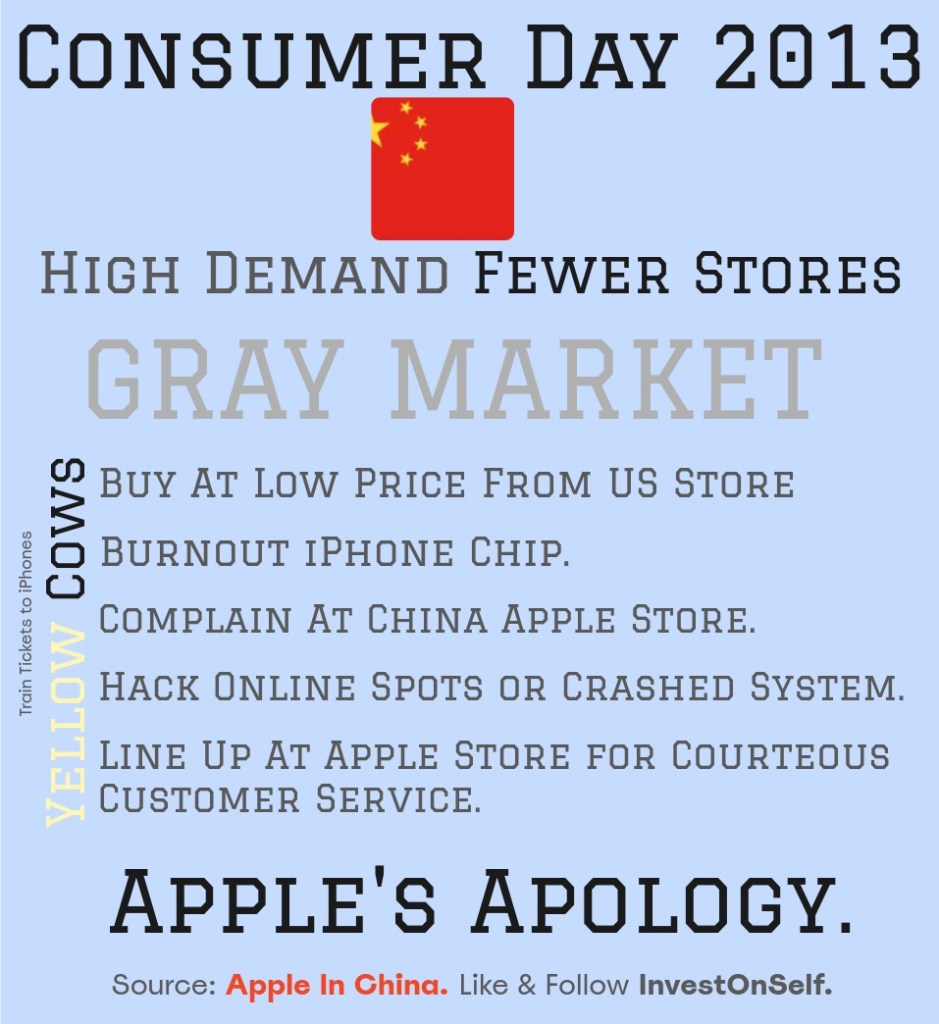

Yellow Cows:

The products were manufactured in high volume, but distribution centres, aka the Apple stores, were fewer with respect to demand in the Chinese market. This made the products costly and gave ample chance to create gray market. The unauthorised resellers, aka yellow cows, took advantage of Apple’s courteous customer service to get new phones in exchange for tampered phones.

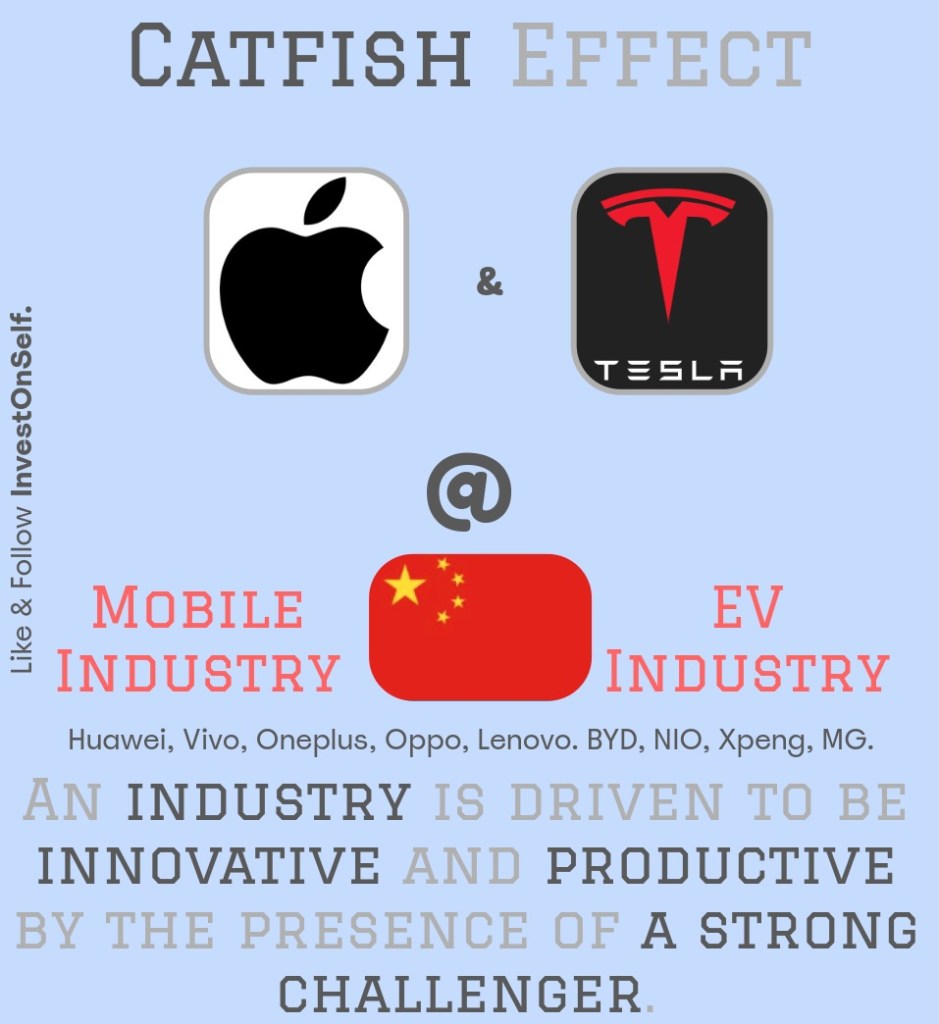

Catfish Effect:

Apple shared manufacturing know-how with contract manufacturers in China for its products. With the latest machines, technology and efficient supply chain strategies, they learnt the process and started manufacturing local brands. That is reflected in the share of Chinese mobile brands, which soared from only 10% in 2009 to 74% in 2014. In fact, Huawei started challenging Apple in the higher-segment mobile market both locally in China & globally until the US ban in 2019.

A similar trend can be found for the Chinese EV industry after the entry of the Tesla manufacturing unit in China.

If you find yourself in the catfish situation, then embrace it to unleash the full potential.

Summary:

- Success demands backbreaking hard work.

- Learn and then earn.

- Set a long-term goal/partnership.

- Be proud, but don’t be complacent.

- Embrace the challenges.

- Both creativity and scale are required for growth.

To contribute or know fascinating facts about tech and psychology, check out/join @ InvestOnSelf.

Leave a comment