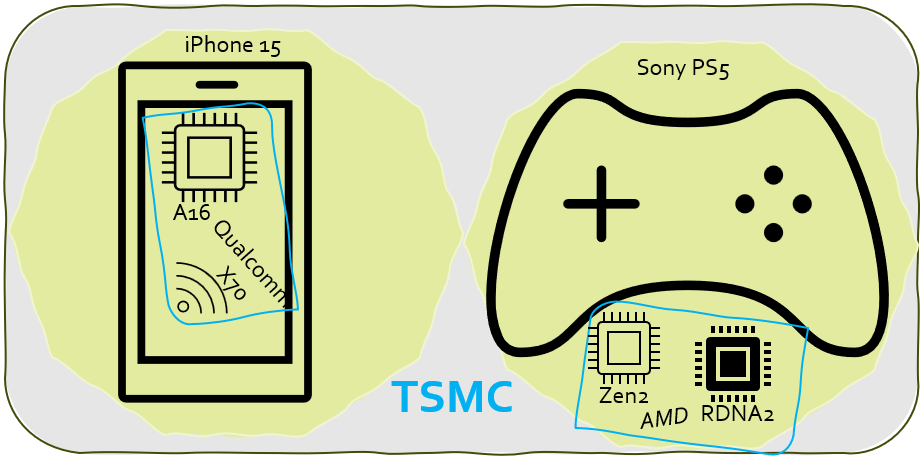

Do you know who manufactures the CPU and GPU chips used in the latest iPhone or PS5 gaming console?

Post WWII, Japan renounced all claims from the Island in East Asia, which is smaller than Japan area wise, Taiwan. After end of Japanese era, many a times China threatened Taiwan, claim it is as part of China with its One China Policy. But with US intervention over time, it became a Herculean task for PLA. How world’s two big economies connected to this island, unlike other 900K islands?

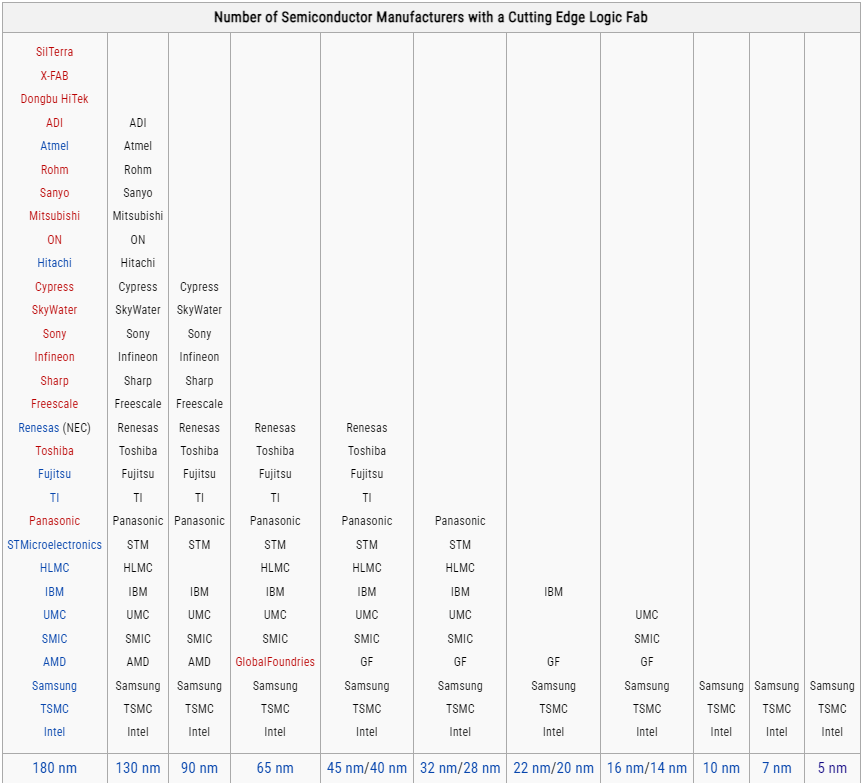

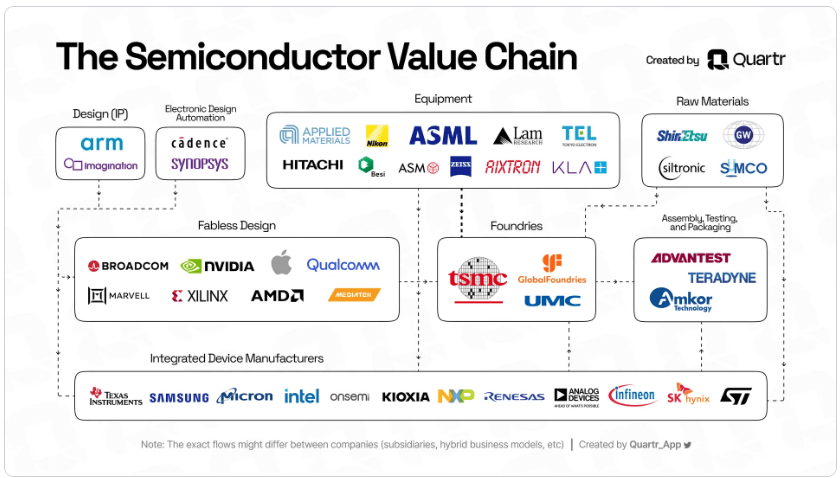

Background of Semiconductor Players

In early 1960, Charlie Sporck was selected to handle Fair-Child Company assembling unit, which was founded by “Traitorous Eight” of Shockley Semiconductor. But he soon realised labour union problem and high labour wage cost in US. So he started looking out other options and then offshored assembly to Hong Kong, Singapore and other eastern countries.

Many other US semiconductor companies like TI, Motorola etc. started following same and offshore assembling to east for below reasons:

- Low wage cost like tenth of American average

- No Labour union

- Efficiency: Twice as fast in comparison to American Labours

- Don’t complain about monotonous work which demand more time

With offshore assembly, these countries started contributing 80% of the semiconductor packaging. But then politician, economist, known as Godfather of Technology in Taiwan, K T Li envisioned to contribute more to the semiconductor supply chain than just assembly to empower Taiwan economy, push Industrialization and bring security from recurrent threats of aggressive neighbour.

Govt Initiative & Semiconductor Fab

In 1968, K T Li was not fully convinced, when Morris Chang and Mark Shephard visited to Taiwan to eastablish TI assembly unit. But he realized later that Semiconductor has more important role and consulted with Morris Chang, who was known to make TI Chip production more efficient, to create a semiconductor manufacturing unit in Taiwan.

He gave Morris free hand and blank cheque to establish a manufacturing unit. He directed other wealthy Taiwanese in textile, agriculture and real-estate, who didn’t abide initially, to invest and take stake in semiconductor fab. Furthermore, he helped in creation of Hsinchu science park, known as Silicon Valley of Taiwan, which has 500 Hi-tech companies now.

Without govt initiative and subsidy, it is nearly impossible to establish semiconductor manufacturing unit by any country. Similar trend observed in South Korean, Japanese, Chinese Semiconductor companies.

Leader and his charisma in building Cutting-edge Fab:

Morris Chang was born in China but moved to many cities in China including Hong Kong during WWII and then attended MIT, worked for Sylvania semiconductor and finally in TI.

During his tenure in TI, he had ideas to make only semiconductor manufacturing unit, but it was unrealized as many thought it was too risky to create standalone fab and idea was simply ignored by TI and Intel.

He took this opportunity to fulfill his long persisting dream. In 1987, he used his contact to convince Dutch Company Philips (with ~28% stakeholder) to partner with Taiwan Govt (with 48% stakeholder) to lay the foundation of TSMC in join venture. It was a project of Taiwanese State.

He used his connection to hire bright minds from US, get technical support, which known as R&D epicentre for semiconductor and most importantly fabless companies as clients, to establish & thrive TSMC.

Real risk was accepting the status quo and keeping short term profit margin right by ignoring long term opportunity.

During 2008 financial setback, he didn’t want to give up foundry dominance despite short term demand crisis. With his semiconductor background & experience, he foresaw this crisis as an opportunity to expand contract manufacturing with rehired fired employees to grab lion share in mobile segment chips.

He created a company culture which is approachable by chip design companies by opening Intellectual property unlike industry giants, Intel, was closed off and thought clients should follow its rule.

Some Key points related to TSMC:

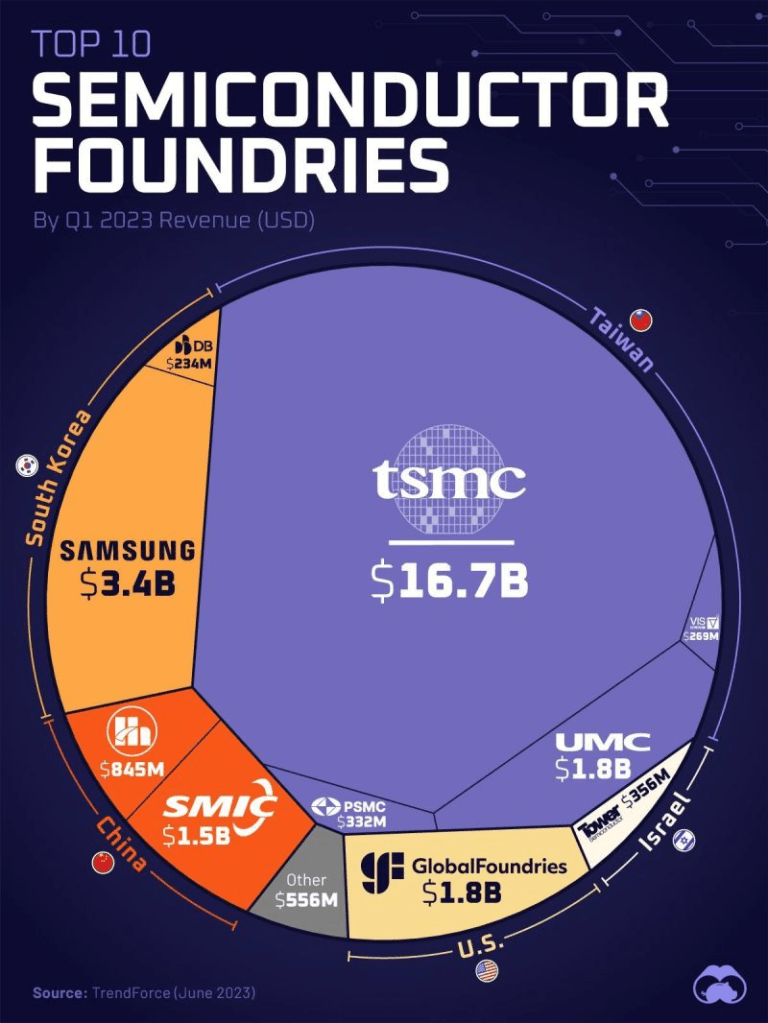

- Monopoly: With 37% market share in manufacturing advance logic chips, TSMC is front runner in this segment after Samsung and Intel.

- Type of Fabs: They have three different types of fabs with respect to Capacity, type of advance equipment used, cycle time, Operating cost etc. These are known as mini fabs, mega fabs and giga fabs. Fab-18 is the most advanced giga fabs which is thrice bigger than AT&T stadium in Taxas.

- There are three broad segment in semiconductor manufacturing. First two segments need to upgrade their fab with cutting-edge manufacturing equipment unlike last one.

- Memory

- Logic

- Analog Chips

- Creating and upgrading Fab is like having a pet shark in the swimming pool. Also, it demands periodic maintenance and bigger fabs for new tools. Only two companies, Samsung & Intel, have upgraded fab apart from TSMC with EUV lithography machine for 10nm and onwards chip manufacturing.

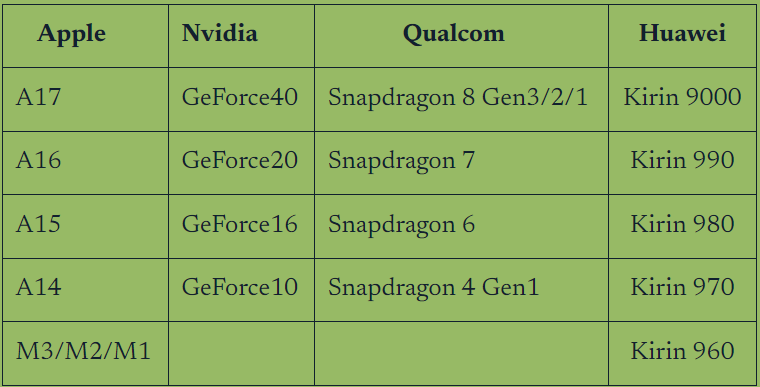

- As company focused only in contract manufacturing, not designing, many big tech companies like Apple, Nvidia, Huwaei etc. partnered with them since decades unlike Samsung, which raise conflict of interest as it deals with both design and manufacturing and produce for it’s own products with other clients.

- With mass production and continuous fab upgrade with cutting-edge equipment’s, production of chip cost far less compared to other competitors. This offshoring helps to thrive many fabless companies around the world and make AI & other nascent technologies a reality rather than building a castle in the air.

- In 2009, GlobalFoundries spined off from AMD to focus only on contract manufacturing backed by UAE Wealth fund, it cancelled 7nm segment with EUV machines (only one machine costs $150 million) plan for their fab, despite having fathomless Oil Money.

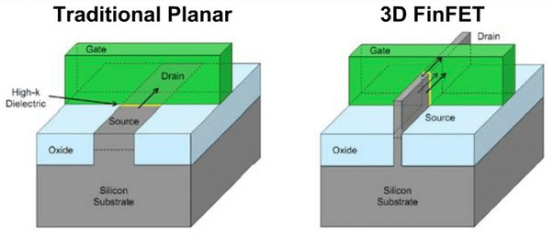

- Father of Moore’s Law, Gordon Moore, thought his predication of doubling IC in every year came to end. Also he was very skeptic about 3D transistor. But TSMC was the first company to use FinFET 3D Transistor, which was complex and required new equipment to accommodate more transistors & more power gain than the 2D model.

- Resilience: If machine breaks down at 1am in the midnight, TSMC start investigation at 2am and try to solve unlike other fabs who look into the issue in the next morning.

- Collaboration: TSMC, under leadership of Morris Chang, created a grand alliance between Fabless companies (fan-out clients) and semiconductor equipment suppliers (fan-in clients) to outplay it’s competitors.

What is protecting Taiwan from Outside threats?

In summary, Semiconductor manufacturing on Silicon, the silicon shield, is protecting Taiwan. Following repercussion will trigger if Taiwan and it’s fab were not safe.

- It is a Herculean task for china to seize the most complex fabs, full of explosive gases and chemicals with precision machines. They need to know technical know-how.

- This will disrupt supply-chain of semiconductor ecosystem where US and it’s allies play a pivot role with supply of raw material to cutting edge machines.

- Catastrophic impact on economy if a company with 37% stake in advance logic chip were offline.

- China’s Assembly will take major hit as majority percentage of chips made in Taiwan, assembled in China.

- Major technological break through and advancements, Like AI, 5G, HPC, FSD etc. will take a major hit and get delayed.

- It will create similar situation, which happened to Russia during Ukraine war, to deploy chips intended for washing machine into missiles.

- Tech companies all over the world (for example Apple, AMD, Nvidia, Qualcomm etc), including Chinese companies like Huawei, Tencent will get impacted. So Apple to Huawei to TSMC, all are betting on peace and stability in this region.

This is an attempt to detail out some facts related to Taiwan, it’s semiconductor giant TSMC. Some information derived from the book Chip War by Chris Miller and other related sources.

Do you know about the company which went againt the tide to become the market leader in graphics design chip company and worth more than $2trillion? Here

Leave a comment